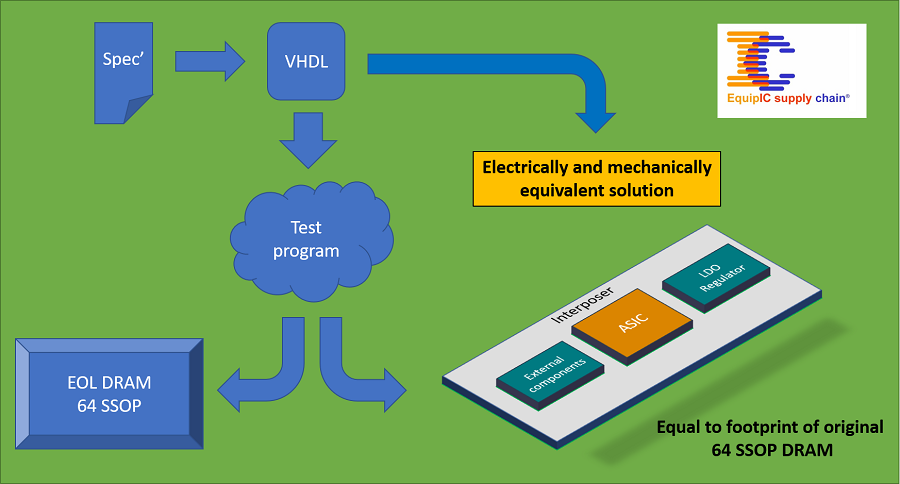

Task : To replace an end-of-life (EOL) video multiport 4MB DRAM with an alternative solution that is electrically and mechanically equivalent.

Followed steps by EquipIC :

- Analysis of original device spec

- Selection of architecture based on today’s technology to mitigate against future obsolescence risk

- Verification of technical feasibility

- NRE development cost estimate & budget agreement with customer

- IC design (coding, testability, layout implementation, foundry review)

- Test program development

- Package development (Interposer solution)

- Silicon validation versus spec

- Ensure long lifetime, low volume production with high quality assurance (among others EN9100, Mil-Std-973 & IPC-A610 class III) fully in line with customer’s own original QA procedures

Key challenges faced and resolved :

- Create a VHDL model that would make an exact functionally equivalent ASIC of the original DRAM

- Provide an interim solution to allow production of the customer’s product to continue whilst replacement ASIC being developed

- Retain original PCB & create a test program to ensure 100% compliance between the original component, the intermediate solution and the final ASIC.

- Keep the customer’s original software without alterations for the replacement ASIC

- Develop a replacement package solution to match the physical constraints of the EOL device with the addition of a low drop voltage regulator within the given footprint

- Provide configuration management, including governing, tracing and documenting each step and configured component of the development process and product in full compliance with military standards/certifications

Final solution : 0.18um ASIC/VRAM in QFN88 10x10mm on 26 x 11mm interposer with LDO versus original DRAM 64 SSOP 26 x 11mm.

Configuration management executed via strict implementation of high-quality procedures and professional project management expertise (PMI certified)